Rapid Crete Concrete Forming Products

Concrete Form Tubes

These cylindrical tubes are used for forming columns, piers, and other vertical elements in various structures. They are produced by continuously rolling layers of paper to make a contractor grade tube that will not bulge or give way when the column is being poured.

Available in widths of 6”, 8”, 10”, 12”, 14”, 16”, 18” 24”, 30” and 36” these 12' tall form tubes ensure stability and precision in concrete placement. They are easy to cut on the jobsite and have a protective wax coating on the inside. After the concrete pour is cured the tube can be easily removed.

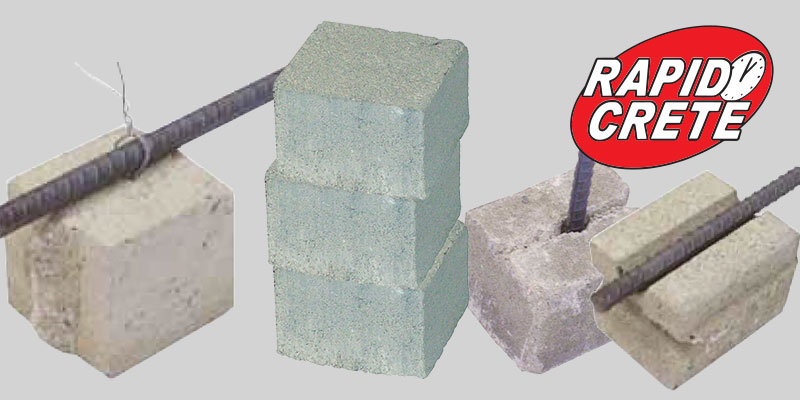

Flat Top, Wire and Combo/Dowel Dobies

Wire Dobies are used to hold reinforcing steel or rebar when you are pouring concrete. Our dobies are made using a 4000 psi concrete mix. Dobies with wire in them will have a lower psi due to the voids that are created when the wire is inserted. The embedded wire can be twisted to hold rebar in place.

Flat Top Dobies provide a stable platform for the rebar to rest on. This helps ensure that the rebar remains at the correct height and position within the concrete.

Combo dobies combine features of both flattop and V-Groove dobies. They have a flat surface on one end and a V-Groove or channel on the other end. This dual design allows for versatility in rebar placement. The flat end provides stability and support, while the V-Groove end can secure rebar in a more specialized manner. Combo dobies are used in situations where a combination of vertical and Horizontal support is needed.

Dowel Dobies are specialized concrete supports used in construction to precisely position and secure dowel bars within a concrete structure. Dowel bars are typically long, cylindrical steel rods that are used to transfer loads and provide continuity between separate concrete sections, such as joints in a pavement or a slab. Dowel Dobies are designed with notches or channels that securely hold dowel bars in place. This ensures that the dowels remain at the correct elevation and alignment within the concrete.

Foam Expansion Joint

A foam expansion joint, also known as a foam joint filler, is a compressible material used in construction to create a gap or separation between concrete slabs, walls, or other structural elements. Made of foam materials. It serves as a cushion to absorb movement and accommodate expansion and contraction due to temperature changes, settling, or seismic activity. Foam Expansion is commonly used in driveways, sidewalks, pools and other concrete applications.

Saturated/Non-Saturated Expansion Joint

Saturated Expansion Joint is composed of a blend of asphalts and mineral fillers formed under heat and pressure between two asphalt-saturated liners. It is waterproof, permanent, flexible, and self-sealing. It can be used in 80% of all control joint applications. It is ideally suited for joints in sidewalks, driveways, streets, and single- and multi-level floor slabs.

A non-saturated expansion joint is one that has not been asphalt impregnated. Non-saturation is typically desired in expansion joints to effectively accommodate structural movement over time.

Steel Stakes

Premium round and flat steel stakes are traditionally used in concrete forming due to their durability and longevity. These stakes can be reused an endless number of times.

These contractor grade stakes come packaged 10 pieces per bundle and are made in round and flat shapes. Available in 12”, 18”, 24”,30”, 36”, and 48” lengths, there is sure to be the right stake for your application.

These steel stakes come with preformed holes to allow speed when forming on the job. Round stakes have a pointed tip and the flat stakes have a concave end for maximum ground penetration.

Rebar Bender/Cutter

This versatile tool swiftly and accurately cuts reinforcing bars. Its robust design ensures ease of use and safety on-site. This bender is designed to cut and bend rebar up to 5/8" (#5 rebar).

This bender features an open cutting jaw for ease and efficiency when cutting bars, simply drop one at a time into the up facing jaw and pull down on the handle. The bender pins are located on the side of the bender and offer the maximum amount of leveraged bending with a portable tool.

With heavy duty replaceable jaws and a 36 inch handle for leverage when cutting or bending, this tool can either be set on the ground or board mounted for stability.

Rebar Bender (Hickey Bar)

This compact portable bender is an ideal way to fabricate and make final adjustment bends to rebar or any other reinforcing metal directly at the jobsite.

It features a 3-prong design with a long handle that allows the operator the maximum leverage to bend and shape reinforcing steel. Simply place the rebar between the prongs and move forward or backward depending on the desired shape.

The ergonomic handle and the simple compact shape make this an excellent choice when working in a footing or other compact space. Since it is lightweight and easy to carry, this tool is convenient and handy for all your projects.